In recent years, kombucha has experienced rapid growth across multiple global markets, establishing itself as a new growth driver in the beverage industry due to its unique flavor profile and drinking experience. The production of a high-quality kombucha depends not only on precise fermentation processes but also on the use of adaptable, stable brewing equipment—an essential factor in achieving the beverage’s signature clarity, aromatic richness of tea, balanced sweet and sour layers of flavor, delicate bubbles, and the subtle note of trace alcohol. Each of these flavor nuances demands higher standards from brewing equipment. With over a decade of experience in beverage equipment manufacturing, Tiantai has mastered the full process requirements for kombucha fermentation, enabling us to provide optimal brewing solutions and configure the most suitable brewing machinery.

Kombucha Fermentation Process

Turning to kombucha fermentation, every chemical reaction during the process requires steady support from specialized equipment. Many brewers encounter issues such as unstable fermentation environments, inability to precisely control parameters, inconsistent product quality, significant batch-to-batch variation, or even contamination and fermentation failure. Kombucha fermentation involves the synergistic activities of yeast strains and acetic acid bacteria. These microorganisms’ metabolic processes determine the beverage’s natural carbonation, acidity, and flavor complexity. The reaction sequence is as follows:

Initially, the carbonation is produced through yeast metabolism: under optimal conditions, yeast decomposes sugars in the black tea infusion, generating carbon dioxide and trace amounts of alcohol. The amount of retained carbon dioxide directly influences the fineness and persistence of bubbles. Many producers face challenges such as insufficient or rapidly dissipating bubbles, uneven carbonation, and a coarse mouthfeel. These issues often stem from inadequate oxygen and temperature control during fermentation, which impacts yeast efficiency, or from misaligned carbonation during subsequent infusion, resulting in poor integration of bubbles with the tea. To address these challenges, Tiantai’s brewing equipment incorporates several design features: first, precise control over dissolved oxygen and temperature during fermentation, providing an optimal environment for yeast activity and ensuring uniform retention of natural carbon dioxide; second, support for customized additional carbonation equipment, allowing facilities to adjust carbonation levels and pressure as needed. This ensures finer, more persistent bubbles that enhance the crisp, refreshing sensation characteristic of carbonated kombucha, while preventing over-carbonation-related issues such as bitterness or explosive bubble burst.

Second is the control of the sweet and sour balance, achieved through oxidative reactions by acetic acid bacteria: these bacteria further oxidize sugars and trace alcohols generated during fermentation, producing organic acids such as acetic acid. These acids, in conjunction with incompletely degraded sugars, create a balanced sweet and sour flavor profile—neither overly tart nor excessively sweet. Industry-wide, a common challenge is the instability of acidity and significant batch-to-batch variability, often caused by the inability to precisely regulate fermentation time, pH, and acidity. Without timely monitoring and intervention during phases where pH and acidity stabilize, subsequent fermentation may lead to excessive organic acid accumulation, resulting in a sour or astringent taste and potentially compromising product shelf life. To address this, Tiantai’s kombucha fermentation tanks are equipped with an all-in-one online monitoring system that continuously tracks pH and acidity fluctuations, accurately capturing the fermentation critical points and enabling automated adjustments based on real-time data. This ensures consistent sweetness and sourness across batches and effectively resolves taste instability at the source. Additionally, the equipment supports customizable fermentation cycles, allowing adjustments based on the desired flavor profile—whether sweeter, more acidic, or balanced—adapting to different beverage formulations.

Finally, regarding mouthfeel delicacy, although kombucha is brewed from tea, it rarely develops the coarse tannic bitterness typical of ordinary tea. Catechins are the primary compounds responsible for the astringency in tea; during fermentation, the levels of catechins and caffeine gradually decline. This reduction preserves the tea’s fresh aroma while enhancing its smoothness. However, many factories encounter issues with intense astringency and rough textures, mainly due to improper control of temperature and pH during fermentation, leading to uneven catechin degradation or incomplete fermentation and residual excess catechins. Tiantai’s fermentation tanks precisely regulate fermentation parameters, effectively eliminating astringency while maximizing the retention of the tea’s natural purity and aroma, ensuring each batch of kombucha exhibits a smooth, rich mouthfeel.

High-quality brewing equipment manufacturer

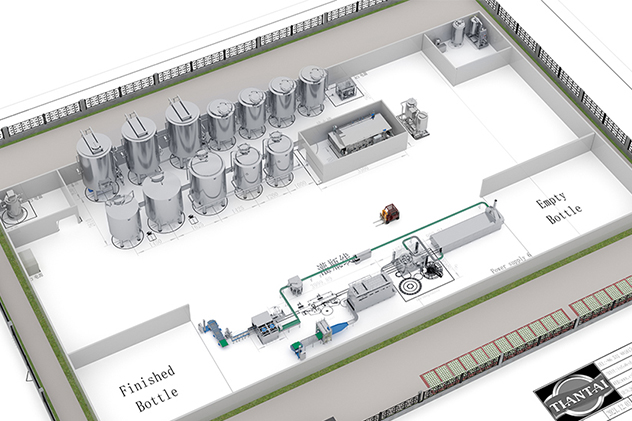

As a manufacturer focused on kombucha fermentation equipment, Tiantai consistently centers on the core requirements of the brewing process, deeply addressing practical factory pain points. We avoid redundant designs, emphasizing precise compatibility. We understand that each kombucha factory has unique product positioning, process demands, and production capacity; No one-size-fits-all equipment solution exists. Therefore, Tiantai’s core competitiveness lies not only in comprehensive quality assurance and solving industry pain points but also in providing fully customized solutions tailored to individual factory needs.