Every kombucha producer develops a unique brewing style. Tea varieties, fermentation temperatures, microbial balance, and flavour strategies differ significantly from brand to brand. As a global kombucha equipment manufacturer and turnkey kombucha factory provider, our role is to supply systems that adapt to any formulation while ensuring hygiene, process control, and production stability.

Below is one example of how a producer uses our technology to brew kombucha at scale. The temperatures and parameters shown are specific to their recipe; our equipment is designed to give breweries the flexibility to adjust these settings to match their own product.

Brewhouse — Stable Extraction Enabled by Automated Thermal & Process Control

In this production line, kombucha begins in a semi-automated brewhouse engineered for consistency:

- Stainless steel boiler with ±0.5°C thermal accuracy

- Free-floating tea brewing tank for full flavour release

- Automated sugar dissolver that guarantees complete dissolution

- Loop-based system for continuous production and CIP cleaning

This producer brews at 76°C to match the needs of their green tea and botanicals.

Our brewhouse allows breweries to:

- Program exact temperatures and extraction curves

- Integrate botanicals without clogging or leaf compaction

- Maintain batch-to-batch uniformity

- Reduce labour through automation

- Prevent bitterness caused by unstable brewing temperatures

Tiantai designs brewhouses specifically for low-tannin kombucha extraction, controlled mixing, and energy-efficient heat transfer—giving brands the freedom to fine-tune their tea base without losing consistency.

SCOBY Tank — Engineered for Microbial Stability & Recipe-Specific Fermentation Profiles

This brewery utilizes a two-phase liquid SCOBY propagation system, which is fully supported by our precision-controlled stainless steel fermentation tanks.

Phase 1 – Yeast Activation

- Conducted in a closed tank at 34°C

- Jacketed tank ensures stable thermal conditions

- Oxygen can be introduced in controlled quantities

Phase 2 – Bacterial Development

- Temperature reduced to 23°C

- Sterile aeration was added to encourage organic acid development

- 2–3 weeks of controlled fermentation create a strong, active starter

Our SCOBY tanks are engineered specifically for kombucha microorganisms, offering:

- Fine control of temperature and oxygen

- Uniform microbial growth thanks to optimized tank geometry

- Full CIP compatibility to protect culture purity

- Reliable replication of each fermentation cycle

This gives kombucha factories confidence that their starter culture remains stable, clean, and predictable as they scale.

Open Fermentation Tanks— Hygienic Natural Fermentation with Temperature Stability

Sweetened tea and liquid starter are transferred to our open fermentation tanks, where the producer maintains a temperature of ~24°C for about seven days.

Key features of our fermenters include:

- Sanitary mesh covers that protect while allowing natural fermentation airflow

- Heavy-duty cooling/heating jackets for temperature consistency

- Precision sampling ports for QC testing

- Easy-to-clean, fully welded stainless steel design

We design open fermentation tanks specifically for kombucha—not beer—ensuring:

- Better oxygen exposure management

- Controlled acidification curves

- Scalable fermentation without microbial drift

- Repeatability across hundreds of batches

This helps producers maintain the flavour signature of their kombucha even as volume grows.

Pressure Fermentation Tanks— Clarification, Flavour Infusion, and Carbonation with Minimal Oxygen Exposure

Once primary fermentation ends, kombucha moves into our pressure-rated conditioning tanks, where several advanced steps occur:

- Clarification

- Centrifugation removes large particles

- Coarse filtration cleans appearance while keeping live cultures intact

- Flavour Infusion Under Pressure. Using HopGun technology—common in craft beer—this producer infuses flavours. The infusion under pressure boosts flavour extraction and reduces oxygen uptake.

- Carbonation & Cold Stabilization

- Kombucha is chilled to 3°C to halt unwanted fermentation

- CO₂ is gently dissolved for controlled carbonation

Our pressure tanks are engineered to:

- Preserve live microorganisms while improving clarity

- Maximize flavour extraction with low oxygen absorption

- Maintain carbonation with precise pressure management

- Ensure alcohol remains within regulatory limits

This gives producers a reliable, food-safe final product with clean, repeatable flavour.

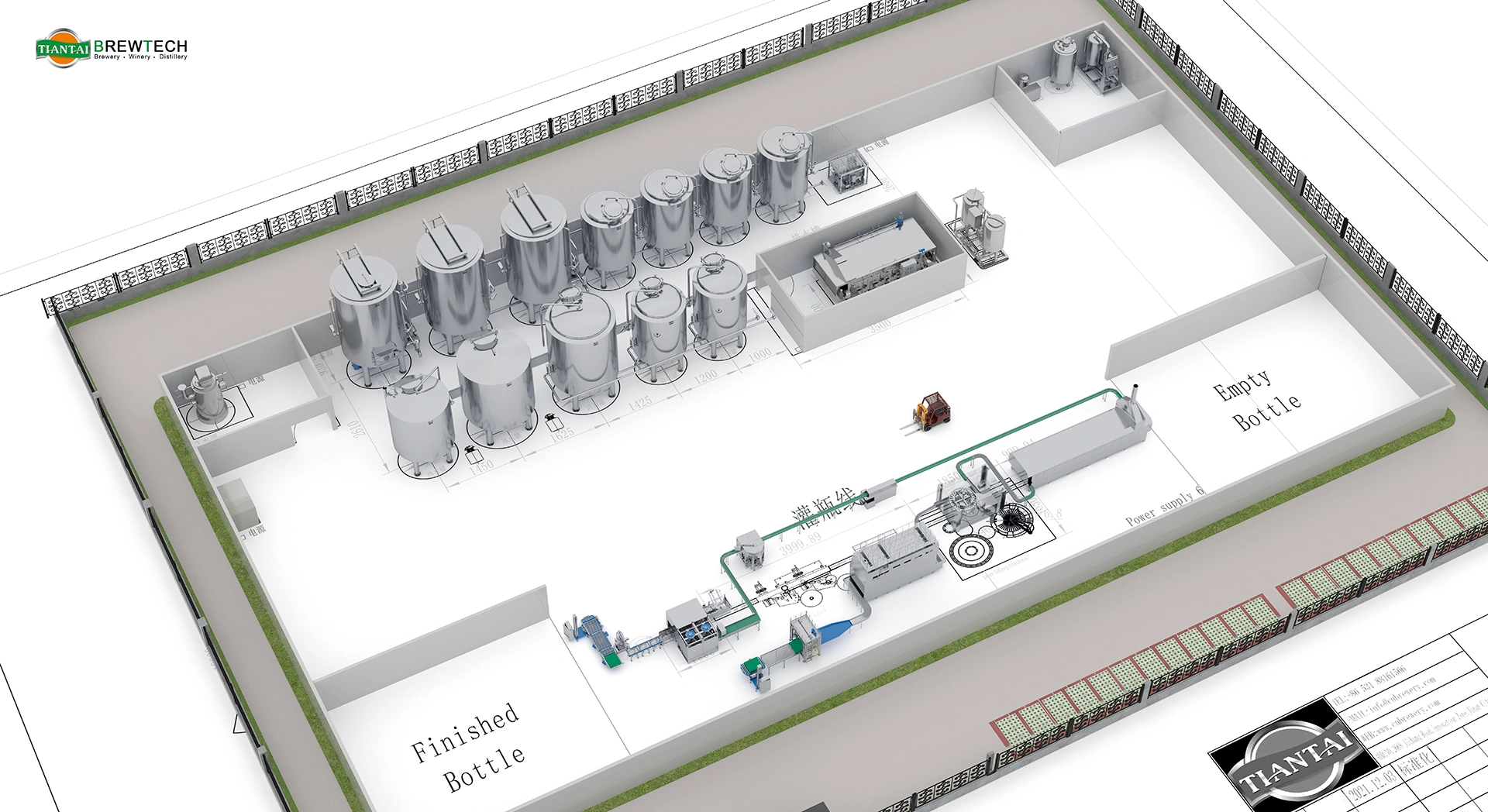

Bottling Line — Integrated, Hygienic Packaging Designed for Living Beverages

This kombucha brewery bottles in-house using a complete line that includes:

- Bottle rinsing

- Counter-pressure filling

- Capping

- Labeling and date coding

We design packaging lines specifically for cold-filled, living kombucha, ensuring:

- Minimal oxygen pickup

- Zero contamination risk

- Accurate fill levels despite natural CO₂

- Smooth operation even with active beverages

Why Producers Choose Our Kombucha Equipment

This brewing example highlights how our systems enable a unique recipe—but our real strength is flexibility. We support every kombucha producer by delivering:

✔ Precision thermal control for tea brewing, SCOBY growth & fermentation

✔ Oxygen and pressure management for microbial stability

✔ Hygienic stainless-steel equipment designed for living beverages

✔ Automated systems that reduce labour and human error

✔ Scalable solutions from pilot batches to full commercial factories

✔ Turnkey services: design, installation, training, after-sales support